Stay up to date

Stay up to date with our monthly e-newsletter

* We will never share your email address & you can opt out at any time, we promise.

Bionic Consortium is one of the leading manufacturers of high performance laboratory and industrial furnaces. They have working relationships with many clients to meet their various requirements. Their wide range of muffle furnace or muffle overn are manufactured to meet the requirements of various research laboratories to make them suitable for their wide range of applications. Be it industry, academic organizations or even environmental testing. These designs come with thermostatic control for temperature regulation. Moreover, they can operate under incredibly high temperature range, which makes these products easy to operate, stable and convenient. Bionic Consortium’s mission is to provide furnace solutions that will suit the needs of their clients in research, education facilities and even industrial processes. Take a look at their brand today to find the most suitable muffle furnace for your purpose.

Bionic Consortium is one of the leading manufacturers of high performance laboratory and industrial furnaces. They have working relationships with many clients to meet their various requirements. Their wide range of muffle furnace or muffle overn are manufactured to meet the requirements of various research laboratories to make them suitable for their wide range of applications. Be it industry, academic organizations or even environmental testing. These designs come with thermostatic control for temperature regulation. Moreover, they can operate under incredibly high temperature range, which makes these products easy to operate, stable and convenient. Bionic Consortium’s mission is to provide furnace solutions that will suit the needs of their clients in research, education facilities and even industrial processes. Take a look at their brand today to find the most suitable muffle furnace for your purpose.

Muffle furnaces are an essential device for precise heat treatment in many industrial sectors, as they are able to provide controlled and uniform heating as the heaters are also well protected. The insulated chamber and heater are interrelated with these components, providing stable output. Muffle furnaces consume less energy due to their superior thermal efficiency, which reduces the overall operating cost. They are easy to operate, they have the option of programmable controllers and safety interlocks that comply with international requirements. In short, a muffle furnace is of great importance when it comes to performing heat treatment in a precise and reliable manner.

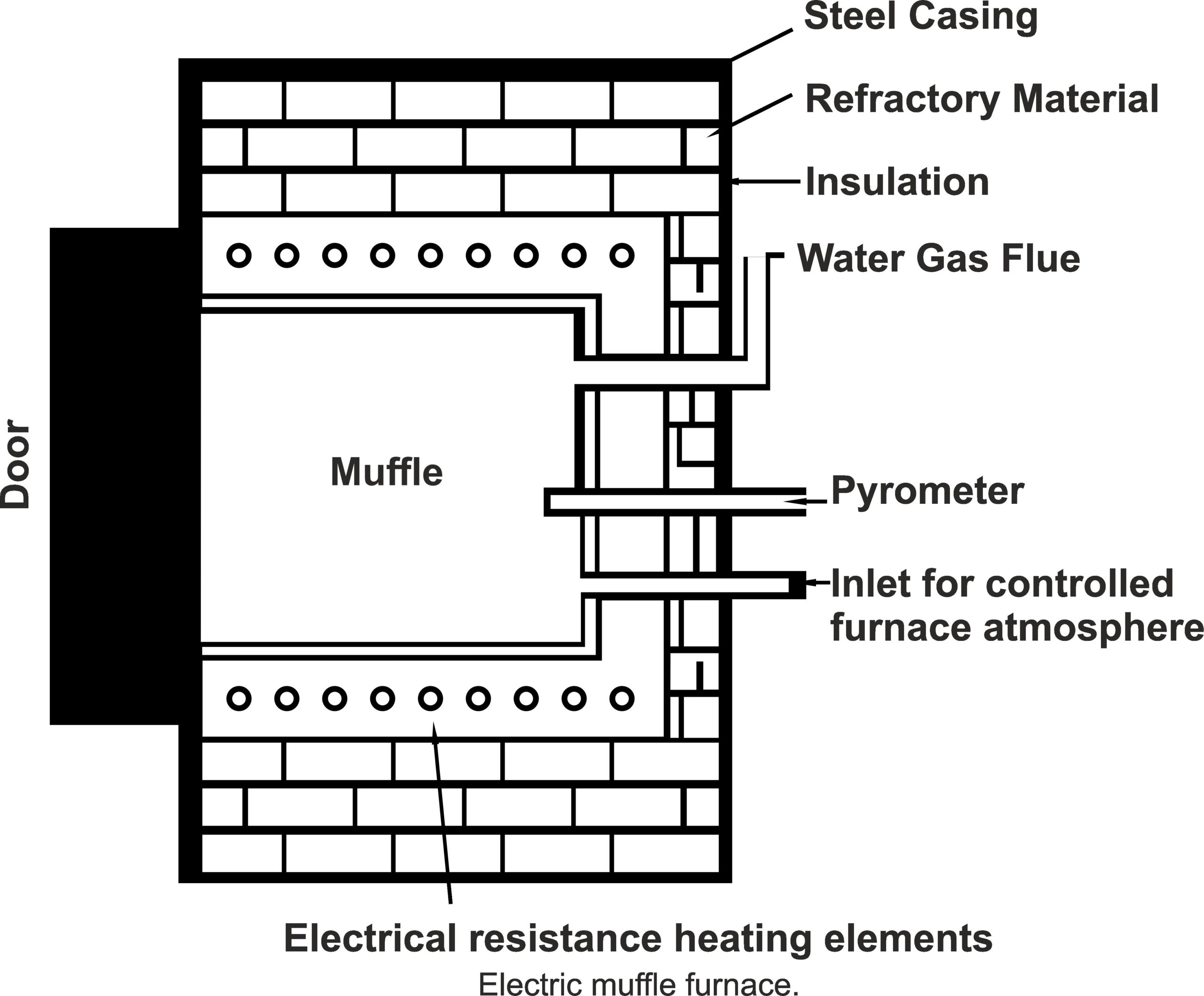

A muffle furnace or muffle oven is a type of laboratory equipment used to heat materials to a great extent without coming into direct contact with fuel or combustion byproducts. This helps to avoid contamination of samples and makes it possible to accurately analyze and process materials. The operation of muffle furnaces is applicable in a wide variety of industries, with special emphasis on calcination, heat treatment, mineralogy, metallurgy, ceramics, and food processing. They have a strong outer metal part, with a heat-insulating construction material inside.

The furnace maintains controlled temperatures within a range of 900°C to 1800°C, depending on the model. The current type, supplied by the Bionic Consortium, has five temperature variations which are 900°C, 1100°C, 1200°C, 1450°C, 1700°C and 1800°C. These furnaces are particularly notable for cost-effectively performing the calcination of minerals and textures when heat-treating metals.

Modern models include electrical heating units that make the furnaces more efficient and versatile than their predecessors. In the past, muffle furnaces were primarily on the market for heat treatments where the work piece was isolated from the gases produced during burning. Today, such furnaces have become effective tools for high-temperature operations, where designed features and clean energy operation are the combined result.

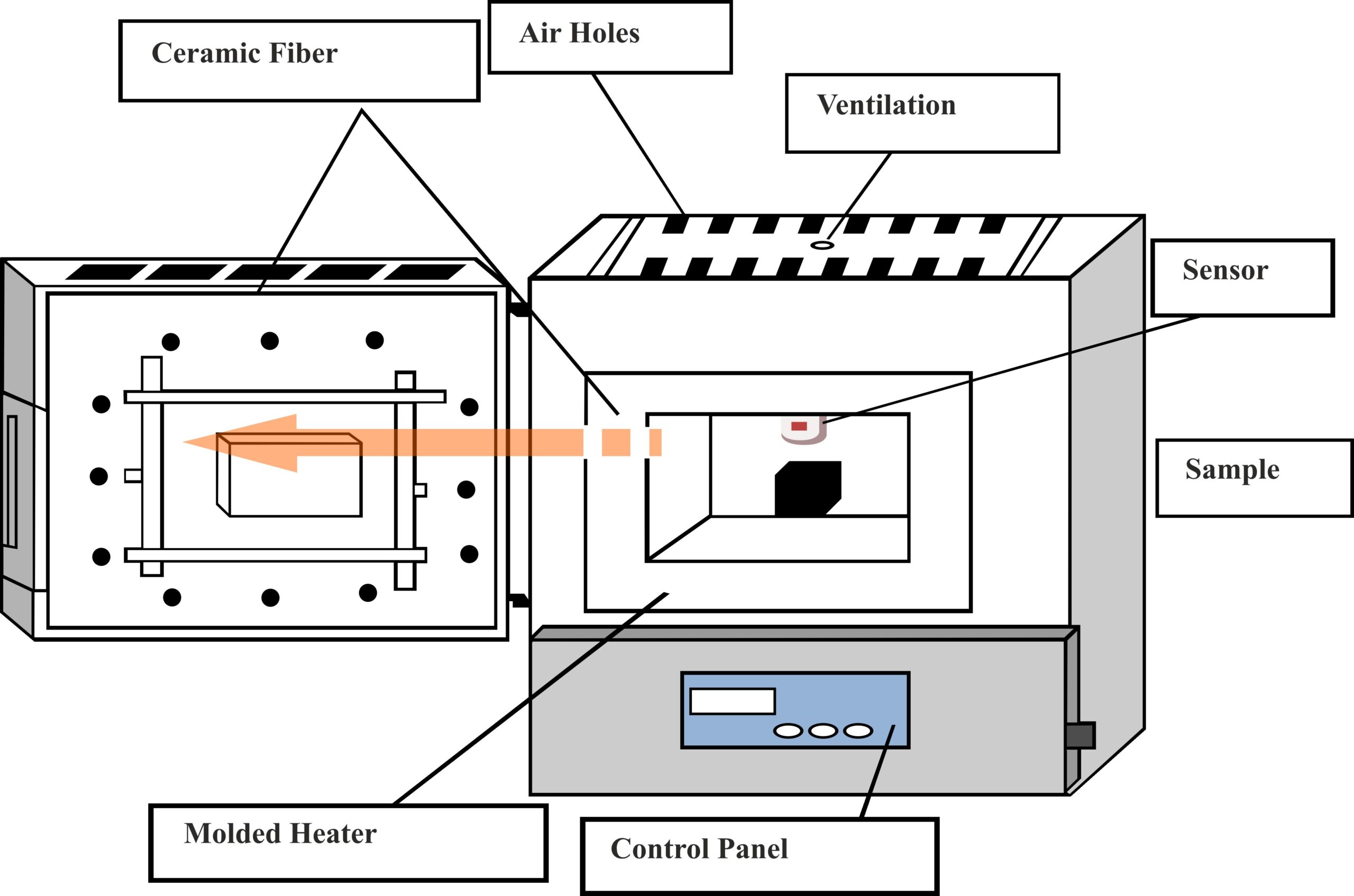

The muffle furnace is a high-temperature heating furnace that is indirect to components and materials. It utilizes heating coils that are embedded in insulating material, thus preventing heat loss and operating in an energy-efficient, self-contained cabinet system. The substance that needs to be heated is placed in a separate chamber called a muffle which is made of a ceramic material such as alumina that can withstand high temperatures and chemical corrosion. This provides self-contained high temperature operating cabinets that are efficient in heating, cooling and recovery.

Muffle furnaces can provide an effective solution to the constant frustration of heating materials without coming into contact with any combustion gases, and keeping them clean in the process. Nowadays, such furnaces are used in various fields such as ashing, heat treatment, and materials research, as most models can be heated in a short time, cooled down quickly, and operated with high efficiency due to their modern design, which allows for greater precision in temperature distribution and control.

Muffle furnaces are mostly used in the laboratory during high-temperature tasks such as glass melting, enamel coating, technical ceramics manufacturing, and welding and brazing.

Bionic Consortium has a wide range of industrial and laboratory furnaces readily available. Their range of products includes box furnaces which are used in applications where uniform heating is desired, atmospheric furnaces which perform furnace functions in an inert atmosphere, and vacuum furnaces which are used for heat treatment under precise oxygen deficiency. They also manufacture laboratory furnaces, which are used for research and small-scale projects, industrial furnaces, which are designed for more intensive work, and rotary furnaces which are used for periodic operations on a continuous process of materials. Also, tube furnaces can be used in cases where very specific heat ranges and heat uniformity are required. These furnaces are built for durability, efficiency, and exceptional performance in a variety of industries.

Muffle furnaces are important equipment used in high-temperature applications that involve the determination of ash and moisture content in samples. They are commonly used in testing the chemical characteristics of ceramics, glass, and enamel coatings. Other applications include analysis of ash melting point or brazing parameters, pharmaceutical or medical sample preparation, materials studies, nuclear waste, quality assurance, and water quality assessment. They are used in various sectors, including:

Muffle furnaces are used in various fields like biomedical, ceramics, glass, etc. which have a wide range of applications. Its price depends on the needs of the customers. The prices of customized muffle furnaces are higher than standard muffle furnaces.

Muffle furnaces are high-performance heating systems that allow excellent and long-lasting treatment of various materials in a vacuum environment. They are economical, simple to operate and have high efficiency. They find applications in the electronics, automotive and machine engineering industries for testing purposes. Their design supports uniform heating and hence makes them ideal for performing thermal treatment on small samples of materials.

A muffle furnace is a heating system that uses an electric control system to convert heat into heat. It uses a heat-resistant heating chamber to increase the temperature within the chamber to the desired material temperature. The system operates based on the law of conservation of energy. It consists of an electronic control unit, an inner chamber, and insulation. The inner chamber houses electric resistance elements, which generate heat by resisting electricity flow. A door safety switch prevents overheating, while a microprocessor PID controller regulates power delivery and displays the temperature on an LED screen.

Bionic Consortium muffle furnaces are economical and highly efficient solutions, featuring dual-shell and triple-wall construction for robustness, safety, and cool touch temperatures outside. Notable features include:

The furnaces designed and manufactured by Bionic Consortium are efficient, safe, and durable, making them suitable for laboratory or industrial use.

Q1. What is a muffle furnace?

A muffle furnace is a heating device used to ensure temperature uniformity as well as to perform laboratory work. It is one of the most common laboratory equipment used in many activities such as ashing or heat treatment of certain products.

Q2. What are the operating conditions of something called a muffle furnace?

Convection muffle furnaces can be purchased at different maximum temperatures. As far as the upper limit is concerned, this parameter is stated in the characteristics of the heating elements installed in the manufacture. Heating elements made of metal wire typically have a maximum temperature of 1000 °C to 1200 °C. Silicon carbide heaters enable muffle furnaces to operate at temperatures up to 1600°C, while molybdenum disilicide heaters enable muffle furnaces to operate at 1800°C.

Q3. What is the use of a muffle furnace?

The muffle furnace is intended for many purposes, which may include for example fusing or ashing, fusing, material heating, annealing, calcination, ignition loss analysis, etc.

Q4. How much time is needed to reach the maximum temperature on a muffle furnace?

According to some research papers, the hybridization temperature is influenced by the dimensions, characteristics, maximum power of the muffle furnace and its material composition. The fastest reaching the maximum temperature would be typical for a laboratory furnace with low thermal mass insulation – this is achieved in about 20 minutes. In contrast to the densest insulation, which may require the use of refractory materials, which may take several hours for maximum output.

Stay up to date with our monthly e-newsletter

Bionics Consortium Pvt. Ltd. is a premier Indian company specializing in the manufacturing, supplying, and exporting of laboratory and scientific equipment, available in both standard and custom designs.

Copyright © 2024 Bionics Consortium Pvt. Ltd – all Rights Reserved.