Stay up to date

Stay up to date with our monthly e-newsletter

* We will never share your email address & you can opt out at any time, we promise.

Bionics Consortium is one of the top leading manufacturer of laminar air flow in India. We provide ISO, GMP, and CE-certified equipment as per your personal requirements. They are known for the equipment that they manufacture or customize. They try to fulfill various pharmaceutical industry rigid requirements as well as laboratory healthcare, among other sectors.

Laminar flow cabinets are crucial equipment that is needed during experiments in the laboratory and research, especially in biological ones. These cabinets are manufactured from smooth, solid steel to abstain from contamination. It also uses HEPA filters, which keep the surrounding air free of any infection or small particles. The air flow is managed in such a way that only clean or free of contaminated air enters the work chamber. Many of the cabinets contain UV clamps that can decontaminate the work chamber. It comes in mainly two configurations, which are vertical and horizontal stands. Laminar flow cabinets are essential to safeguard the work area from dangerous infection or contamination.

It is essential in conducting scientific research, doing medical operations, and production processes. It helps to maintain a clean environment in the work chamber. These kinds of workstations are vital for the experiments, which contain a high risk of contamination while performing. It also protects biological samples and sensitive materials, which ensures the accuracy of the results. It also helps in many industrial applications, including laboratories, pharmaceutical manufacturing, and semi-conduction production.

A laminar flow cabinet is a research device used in various scientific research and operations to protect a biological culture or sensitive material from contagion. It uses HEPA filters that promote a uni-directional flow of air in the cabinet, which acts as a barrier between the inside environment and the outside environment. It is different from a fume hood that is more focused on protecting the user than disinfecting or sterilizing samples from contamination. The fume hood protects it by removing contaminated air away from dangerous particles. Laminar flow cabinets do not protect users from contamination or any other dangerous or risky particles. It comes in two configurations, one vertical and one horizontal. It also contains UV clamps, which are needed for disinfecting internal surfaces before use. The cabinets are manufactured with durable stainless steel with no gas or joints so that microorganisms and particles do not gather and are inreplaceable for biological experiments.

Regardless of similarity, a laminar flow cabinet is easily confused with a biosafety cabin or fume hood. As fume hoods are primarily manufactured for worker protection apart from material contamination. The only difference between a fume hood and laminar flow cabinets is that a fume hood draws air out of the work chamber; on the other hand, laminar airflow cabinets draw clear air into the work area to protect samples rather than users.

Image credit to microbenotes.

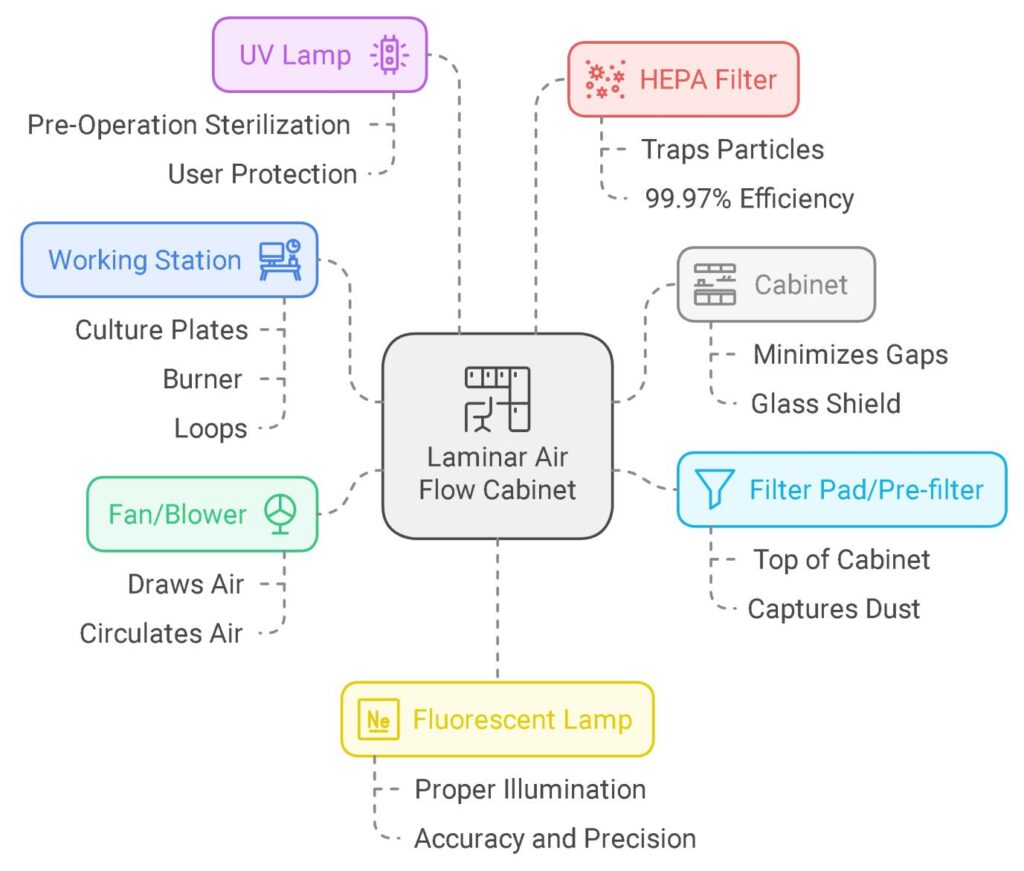

Cabinets: The laminar air flow cabinets are manufactured from durable stainless steel and are designed with no gaps or joints. It helps to prevent the accumulation of spores. It isolates the inner environment from the outside and has a glass shield at the front. This shield is fully openable and has two openings for hand access. The cabinet serves as the important structure for the laminar flow hood. It contains all other needed components for creating a sterile environment in the cabinet for various tasks.

Functioning mechanisms or working station: A plane work base is provided inside the cabinet where all the operations are carried out. This area contains culture plates, burners, and loops for various operations. It has stainless steel surfaces that are prone to rust. The dimensions of the workstation make it possible to work on a large scale. It also helps in simplifying the sterilizing process that ensures there is no contamination of the material and samples during operation or after use.

Filter pad/pre-filter: There is a filter pad installed on the upper part of the cabinet. Which helps to pass only clean air to the cabinet. It prevents dust and some microbes from entering the cabinet. There is also a pre-filter that removes larger particles before the air enters the HEPA filters. which maintains the cleanliness of the HEPA filter and increases its lifespan. which guarantees the efficient and hassle-free performance of the system.

Fan/Blower: A fan is placed under the filter pad to circulate it within the cabinet. This fan helps to flow air towards the HEPA filters. Preventing remaining microbes and small particles from passing through. Air is sucked from the pre-filter by the blower and then passes through the HEPA filters. Afterwards, it is forwarded towards the work area, ensuring a continuous supply of clean air.

UV lamp: Some laminar flow hoods come with ultra-violet lamps. This is used to disinfect the inside chamber of the hood before using it. These lamps should be used 15 minutes prior to operation so that the user is protected by UV exposures. Also, when the cabinet is not in use, the UV lamps remove microorganisms, ensuring a clean environment for procedures.

HEPA FILTER: The high-particulate air (HEPA) filter is vital for circulating clean air or forming a sterilize environment in the cabinet used during operations. It purifies the air, preventing harmful particles like fungi, bacteria, dust, or any other kind of microorganism. This filter eliminates 99% of the small or dangerous particles. This ensures that the air inside the cabinet is not only recirculated but also clean and sterilized free of contamination.

Fluorescent Lamp: Fluorescent lights are placed inside the cabinets to ensure proper lighting during laboratory research or operation. As the saying goes, lighting plays a crucial role in achieving accuracy and efficiency in tasks performed at workstations.

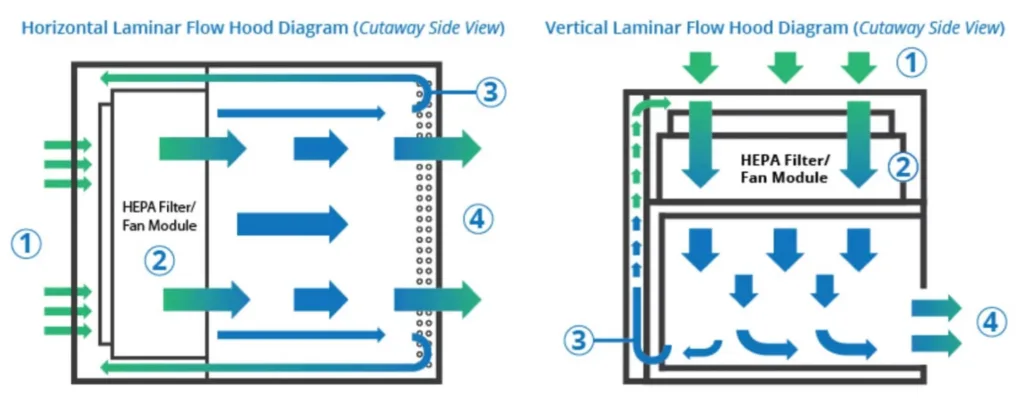

In a vertical flow cabinet, air is moved from the upper section of the cabinet to the lower section of the cabinet. This bench is easier to manage in respect of horizontal air flow hoods as it doesn’t require much depth and space. Thus, the chances of uncontaminated air flow in the cabinet are reduced to none. Vertical laminar flow cabinets can be considered a safer option as they don’t purge air directly towards the user performing the research or experiment.

Horizontal laminar flow cabinets are used by circulating air from behind the work surface, which passes through a HEPA filter. The controlled, clean air then flows parallel to the workstation at a uniform rate. Which ensures that the working chamber always has a sterilized and clean environment.

On the other side, this kind of air flow can be dangerous as it goes directly at the operators. While such cabinets are rarer than vertical cabinets, which have air circulation from the top and go down towards the working chamber before exiting. Vertical cabinet blowers and filters are installed at the top, which produces a different air flow pattern.

In a horizontal laminar flow hood, the filter is placed on the rear wall of the cabinet. Under normal circumstances, the HEPA filter in this case, air flows through the rear side of the hood and is filtered. Once filtered, the air moves forward in the direction of the work. In a vertical laminar flow hood, air is pushed from the top of the hood into the workspace. The upper ventilation panel on the workspace moves the air flow from this panel forward in parallel and perpendicular directions. The filter found in these hoods is placed on the top panel of the unit. This is also the case with a vertical LFH, although in this case the ‘direction’ is downwards towards the work area. This is in contrast to a horizontal LFH, where the filter has a cover on the rear wall.

Laminar airflow cabinets are crucial for maintaining a sterile environment. During experiments and operation, the air is supplied to the cabinet in a vertical and clear air flow from top to bottom. First, the air passes through a prefilter that gathers large particles. Afterwards, remaining air then passes through a HEPA filter that prevents remaining small particles or microorganims such as bacteria, molds, and other remaining contaiminated particles. A fan is also beside the HEPA filter that supplies clean air in a uniform motion towards the working chamber. Converging it from external contamination agents. Some exits are through small vents at the rear of the cabin, while the sides of the cabinet are kept completely sealed so that outside air does not enter the cabinet.

To prepare your work area, start by cleaning the space around the device to avoid dust getting into the filter. Remove any obsolete devices or trash items. If ventilation is needed, close the lid and run the fan for 10-15 minutes. Once done, remove the lid and use 70% ethanol to clean all internal surfaces. After that, put the lid down, make sure it is secure, and turn on the UV lamp, stand back for 15 minutes. After the time period has passed, turn off the UV lamp and turn on the internal light to start your work. In cases where your work is long, make sure the air is changed regularly using a blower. If your work is hazardous work, the lid must be kept closed before turning on the fan.

Stay up to date with our monthly e-newsletter

Bionics Consortium Pvt. Ltd. is a premier Indian company specializing in the manufacturing, supplying, and exporting of laboratory and scientific equipment, available in both standard and custom designs.

Copyright © 2024 Bionics Consortium Pvt. Ltd – all Rights Reserved.