Stay up to date

Stay up to date with our monthly e-newsletter

* We will never share your email address & you can opt out at any time, we promise.

Most manufacturing processes require surface preparation to ensure that the final product is durable. The degreasing furnace is a key piece of equipment at this stage, and it can remove oil, grease, and other contaminants from metal surfaces through chemical or heat-based methods. In this article, we will delve into the various types of degreasing furnaces, their applications, and how they help improve production efficiency and product quality.

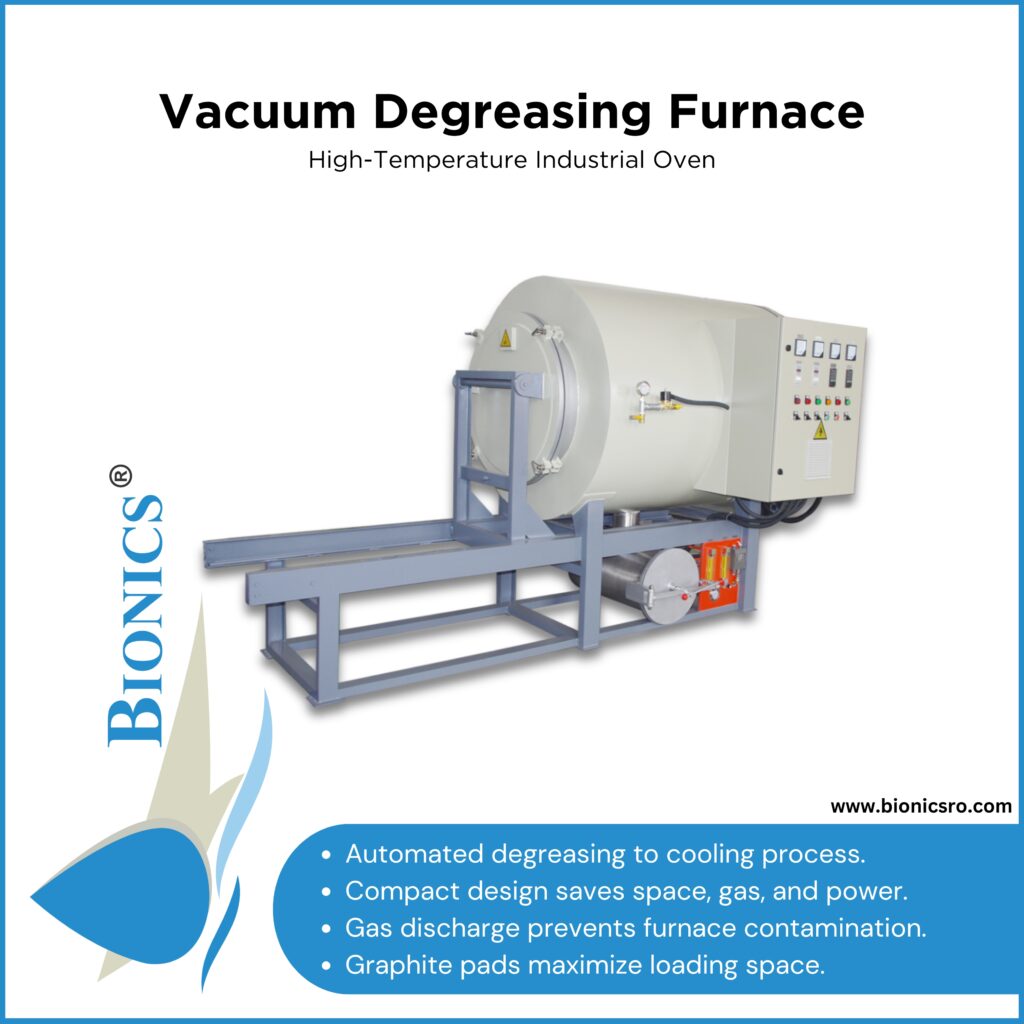

Bionics Consortium is one of India’s top manufacturers that exports different models for vacuum degreasing furnaces. Their range of furnaces comes with sealed chambers and multi-stage water-cooled grease catchers for optimum degreasing, which are known for their customisation features. In addition to easy maintenance, nickel-chromium heating elements are used as well as heat shields. Such units also feature a carrier gas degreasing system, internal circulation cooling, and a special steam grease cleaning process for enhanced performance.

A high-temperature industrial oven designed to remove impurities from metal surfaces by means of direct contact with heat energy is called a degreasing furnace. This device is commonly used in automotive, aerospace, electronics, and general manufacturing sectors where vaporisation of oil or grease ensures accuracy and cleanliness.

The horizontal single chamber design allows for efficient water cooling in the degreasing furnace, while the stainless steel furnace body insulated with high-temperature fibre contains an internal stainless steel degassing chamber where heating elements are located. A door seals off the heat to prevent loss; integrated vacuum sintering can be done in either vertical or horizontal configuration depending on customer requirement. Heating components as well as insulations may be altered depending on temperature needed using graphite, molybdenum, or tungsten materials; easy serviceability is achieved through having a removable hearth within such systems, while advanced hermetic ovens together with a water-cooled disc degreaser ensure better grease removal and collection; an adjustable flow rate is made possible by gas degreasing systems, which also offer innovative vapour degreasing technology that guarantees the best cleaning performance.

VDF series vacuum degreasing furnaces are mainly used for cleaning ceramic injection moulded (MIM) parts made of metals and non-metals. Some of the materials include stainless steel, nickel, ferroalloys, titanium, and high-speed steel, among others. Applications range from medical device components such as dental and orthodontic products to mobile phone accessories like shells, keys, buttons, etc. Computer hardware components are also commonly treated in these machines.

Optional Extensions

Vacuum System

To get rid of gas inclusions, the vacuum system consists of a two-stage water-ring vacuum pump and rotary vane vacuum pump with a filter. It is recommended that you use pneumatic vacuum valves to ensure they don’t fail. Every pipe used in this system is galvanised so that it can last for a long while being at a place where it can be easily seen.

Inflatable system

The nitrogen charging system is provided with a vacuum degassing furnace, which also has adjustable gas flow and rapid cooling functions. The furnace is equipped with an electric contact pressure gauge, automatic intake valve closure, and safety explosion-proof valve to ensure precise control over different pressures within a certain range necessary for safe and effective degassing.

Stay up to date with our monthly e-newsletter

Bionics Consortium Pvt. Ltd. is a premier Indian company specializing in the manufacturing, supplying, and exporting of laboratory and scientific equipment, available in both standard and custom designs.

Copyright © 2024 Bionics Consortium Pvt. Ltd – all Rights Reserved.