Stay up to date

Stay up to date with our monthly e-newsletter

* We will never share your email address & you can opt out at any time, we promise.

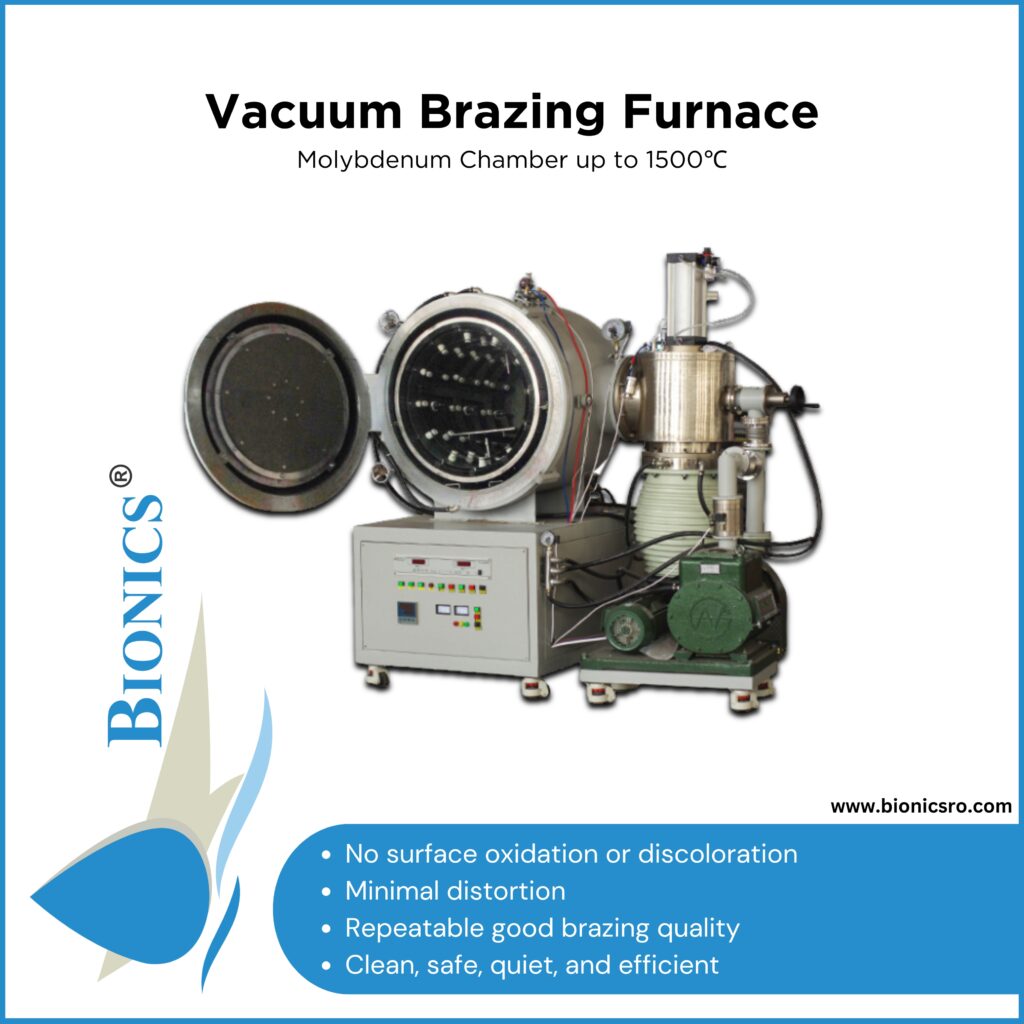

High precision, robust metal joints are produced using vacuum brazing furnaces, which are sophisticated metallurgical industry equipment. It is an improvement over the traditional methods as this process entails melting of filler metal at high temperatures while avoiding the melting of base materials. These advanced, compact furnaces for industrial applications in aerospace have a pumping system, power supplies and cooling systems for various heat treatment processes. It is expertize for Bionics Consortium Precision to perform vacuum brazing services in critical applications including aerospace industry, biomedicine and electronics where they are joining ceramic-to-metal and metal-to-metal assemblies. The company consists of highly experienced engineers who can choose suitable fixtures, joint designs, alloys, and processes for every application.

Bionics Consortium is a leading Indian company specializing in the design and production of high temperature vacuum brazing furnaces. Our brazing furnaces are employed in hundreds of applications throughout the manufacturing process across various industries. The praised accuracy, efficiency and control associated with brazing furnaces mean that these devices are indispensable when creating anything from intricate multi-joint assemblies to crucial turbine components used in renewable energies.

A furnace meant for vacuum brazing is an industrial machine that employs controlled vacuum environment to melt filler metals above 450°C so as to join metals together. Through capillary action bonding can then be achieved between base metals (ceramic like) and steel at temperature range 800°C-1150°C under vacuum atmosphere conditions. The furnace removes oxygen thus controlling oxidation while also heating fillers up to brazing temperature, hence making it ideal for joining materials which oxidize easily.

In the furnace-brazing process, dissimilar lower filler metal is used to form connections among metallic parts under controlled conditions within a high vacuum environment.

Vacuum brazing furnaces are available in various configurations and sizes, optimized for specific materials and processes, including high and low temperature applications, continuous operation, and special functions such as diffusion welding.

To join two or more metals, filler metal in the form of powder, paste, or pre-formed alloy is placed at the junction areas inside a furnace during vacuum brazing. The high vacuum that is created in the furnace results from purging it of air and impurities. Oxidation that can weaken the joints is prevented due to the lack of oxygen. As a result, heating these parts to a temperature higher than the melting point of the filler metal but lower than that for the base metals creates a molten state where capillary action occurs before solidification.

Choosing this method as an option for joining diverse materials has many benefits associated with it, such as:

Assess the experience, equipment and expertise of a vacuum brazing service provider in order to guarantee successful implementation of advanced manufacturing processes.

This process combines metals via a brazing filler. It takes two elements which have been prepared and books them in a drawn out vacuum furnace to the temperature of brazing for about (800-1150°C), holding them there for 10 minutes and then cooling down to solidus. This makes it possible to join ceramics and steel. The correct vacuum level must be continuously maintained throughout this process, which can also be done in an argon atmosphere.

A typical vacuum brazing treatment is as follows:

Characteristics associated with vacuum-brazed Furnaces are:

Industries we serve include: tool manufacturing, aerospace, automotive, medical, semiconductor, etc.

Advantages of Vacuum Brazing Furnace:

Bionics Consortium high-temperature vacuum brazing furnace can reach 1500°C, which makes it possible to perform brazing of stainless steel, CBN, and diamond tools under vacuum. This capability also allows for sintering and heat treatment of other materials at higher temperatures because the device structurally features high vacuum and temperature possibilities.

A vacuity brazing oven is employed as a finalizing technique for simple and difficult parts. Brazing ovens are more suitable than other joining techniques for multiple metal pieces because of their comparative advantage.

Furnace brazing finds application in different materials and metals. Controlled atmosphere brazing ovens are normally used to join stainless steel components for accurate connections. Nickel, copper, and silver serve as alternative metals commonly applied to braze filler materials.

Stay up to date with our monthly e-newsletter

Bionics Consortium Pvt. Ltd. is a premier Indian company specializing in the manufacturing, supplying, and exporting of laboratory and scientific equipment, available in both standard and custom designs.

Copyright © 2024 Bionics Consortium Pvt. Ltd – all Rights Reserved.