Stay up to date

Stay up to date with our monthly e-newsletter

* We will never share your email address & you can opt out at any time, we promise.

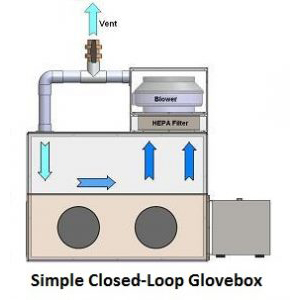

The use of filtration glove boxes in closed system environments serves to safeguard the sensitive materials and those who handle them from any form of contamination.

These boxes are applied in industries such as electronics, pharmaceuticals, and research whereby they help maintain a clean environment by removing gaseous substances and floating solid particles.

This prevents harm to both the products being worked on and workers themselves.

The glove box filters include full-circumstance filtration, product discharge in an inert environment, drying, et cetera; some of them are custom-made to meet certain specifications.

A filtration glove box is a closed chamber for managing dangerous or delicate substances under controlled environment. It employs built-in filtration system such as HEPA filters to get rid of impurities that can affect users and materials. They are ordinarily seen in pharmaceutical or chemical powder producing labs, with many uses in microelectronics, optics, cell culture, medical devices, genomics, proteomics and cell biology amongst others. The Bionics Consortium glove box systems provide accurate atmosphere control and the containment of harmful substances.

The filtering types and sizes of glove box filters like HEPA and ULPA are different. While the HEPA captures bigger particles, the ULPA catches smaller ones at lower airflows. They last for 5 to 8 years.

Filtration glove boxes are used to safeguard both staff and products through the removal of airborne dusts and powders by employing HEPA or ULPA filtration. Commonly used at laboratories manufacturing pharmaceutical or chemical powders besides suitability for a range of applications such as optics, microelectronics, cell culture, medical devices and genomics. Such systems can be configured for either positive or negative pressure and come in open-loop, closed-loop, and adjustable-flow designs.

The glove box contains HEPA filters that serve as airtight barriers to protect the operator from harmful dust and particles in the air.

This glove-box has applications in pharmaceutical research, nanotechnology, biochemistry, and cleanroom. It meets ISO Class 1 atmosphere containment conditions for oxygen leak rates and achieves ISO Class 3 conditions for airborne particulate cleanliness.

Drug powder introduction is achieved by means of the static-dissipative PVC chamber, which includes a mixing/packaging station and ultra-low penetration air filters to promote a low-humidity, static-safe environment. Sample transfer is accommodated through dual-sided air locks, while an automated nitrogen control system maintains a sub-ambient RH set point. As a result of this, ionising nozzles are provided to ensure that the process remains clean and free from static charges.

Its usage spans across various industries, such as:

Dual HEPA filter open-loop filtration model which has the following characteristics:

The glove box filters include full-circumstance filtration, product discharge in an inert environment, drying, et cetera; some of them are custom-made to meet certain specifications.

The product includes an acrylic viewing window, Add-A-Valve Kit, Anti-Static Ioniser Fan, Balance Vibration Isolator, Blower Foot Switch, Complete Valve Set, Diaphragm Pumps, Electrical Power Strips, etc.

Stay up to date with our monthly e-newsletter

Bionics Consortium Pvt. Ltd. is a premier Indian company specializing in the manufacturing, supplying, and exporting of laboratory and scientific equipment, available in both standard and custom designs.

Copyright © 2024 Bionics Consortium Pvt. Ltd – all Rights Reserved.