Stay up to date

Stay up to date with our monthly e-newsletter

* We will never share your email address & you can opt out at any time, we promise.

In dentistry, sintering furnaces have become a centrepiece for the production of high-quality ceramic and zirconia restorations. These furnaces are very important in improving the properties of zirconia by eliminating porosity through the process of high temperature. They are essential in any modern dental laboratory or clinic due to their automated capability as well as pre-programmed processes.

To cater for requirements in contemporary dentistry, it is necessary to integrate high-temperature molybdenum disilicate heated ovens into dental laboratories that can work with a wide range of different zirconia materials.

Sintering is a process where materials are heated to below their melting point, forming a green body that hardens and solidifies, gaining final properties.

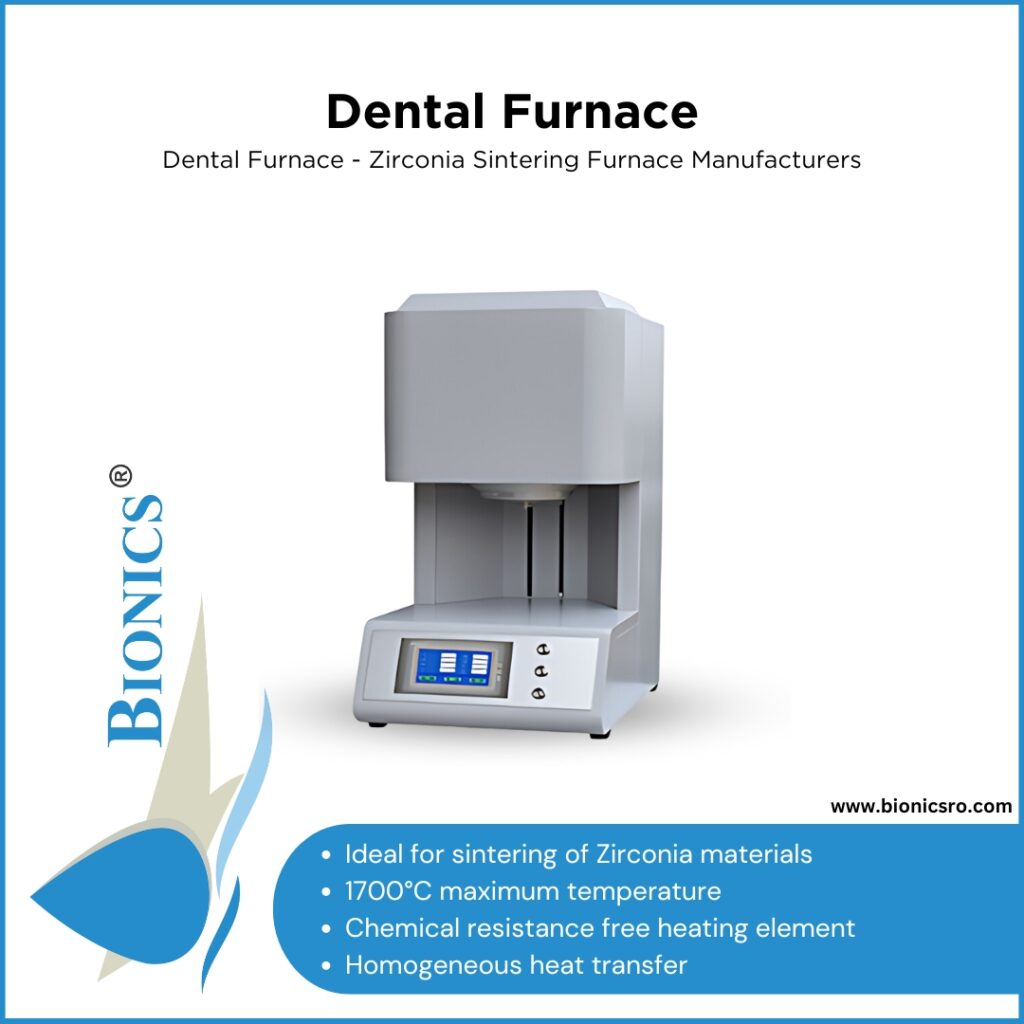

Bionics Consortium is one of the leading manufacturers and suppliers of high-quality dental furnaces in India The company also offers preheating furnaces for casting, sintering ovens for zirconium oxide powders, and translucent zirconium oxide and CoCr metallic alloys. It has also been known to provide stress relieving annealing after laser sintering. Also, they create vacuum furnaces for firing common veneering ceramics under a normal atmosphere or under vacuum. There exist dental furnaces with programmable temperature control, motorised bottom doors, etc., cylindrical heating chambers, along with MoSi 2 heaters. Their single program and 32 segments make them a perfect fit for high temperature zirconia sintering.

In the area of dentistry, sintering furnaces, otherwise known as dental ovens, play a big role since they enable the processing of dental porcelain material, which is reliable enough to be used as restorative material. This requires automatic and programmable temperature control systems on these ovens so that the best results could be obtained. The same machines are employed in various applications within this field, including making ceramic prosthetic components such as crowns, bridges, onlays, and inlays at dental labs. The equipment available on the market today has touch-screen interfaces, is pre-programmed, and can be connected to the internet. In this process, ceramic particles are formed as the final restoration is made stronger, more durable, and also for better translucency.

There are different dental furnaces, which include ceramic combination furnaces, ceramic furnaces, and sintering furnaces. Ceramic furnaces are used to fire traditional ceramics, whereas combination furnaces can process pressable ceramics with the necessary pressure. Sintering furnaces deal with zirconia after milling, taking it through very high temperatures. There are glazing furnaces used to set certain stains and glazes that add final shade details to a porcelain reconstruction.

However, ensure you buy a furnace that can handle the materials you use in your practice or laboratory when purchasing one. Ensure that you get easy-to-clean ovens that can be maintained well prior to and after use. Just like any other equipment, when buying a furnace, it is advisable to go for reputable brands.

Dental furnace refers to an instrument used in dentistry either to heat or cool teeth and gums, especially as it concerns heating them up so that they become hardenings in their final state, where these happen to be ceramic materials employed making crowns, bridges, and inlays used in dentistry.

The major aim of a dental furnace is to eliminate the wax pattern from an investment mould or porcelain, thus burning out the former. This process is essential in the production of ceramic dental restorations. Different types of dental furnaces have been developed, and each has specific roles it performs within a dental laboratory.

One such example is ceramic combination furnaces; these are used during most dental laboratory procedures because they are multi-purpose machines that fire and press ceramic materials. Therefore, they are versatile enough to bond onto almost any type of tooth restoration material as well as bond during multiple steps in the laboratory fabrication process.

Often referred to as sintering furnaces, these ovens play a role where they cause only sintering to occur by heating up materials without necessarily melting them down.

These furnaces are often combined into one system or grouped together with heated conventional and glass ceramics for milling, stacking, waxing up, and investing prior to pressing.

Dental furnaces come with superior characteristics such as being programmable digitally, touch screens large in size, high temperature precision, and high vacuum accuracy. One key characteristic of dental burnout furnaces is their fast heating rate, where temperatures can increase by 100 degrees Celsius per minute. This feature comes in handy, especially when used for metal-casting wax burnout or lithium disilicate press ingots casting wax burnout.

For instance, these devices are used in firing/sintering operations involved in manufacturing dental opacifiers, dentin, or enamel components, among others, while on the other hand, oxidation of metallic substructures occurs before porcelain firing processes begin, besides melting pressable ceramics, finishing stain firing, glaze firing, etc. Usually, the temperature ranges for these processes are between 600 °C and 1050 °C.

Modern dentistry values dental furnaces, for they make it possible to carry out different laboratory works by dentists in the practice and reduce collaboration with external clinics. In this way, customisation is increased alongside productivity, and this leads to accurate and controlled high-temperature procedures that are aimed at improving the level of dental services provided. Bionics Consortium offers dental furnaces with sintering, ceramic combination, and firing features that help meet the ultimate requirements of dental business companies. These advanced ovens have the best properties and characteristics that include high rates of heating as well as precision temperatures. Bionics Consortium is a reputable company in dental furnace manufacturing that provides innovative dental solutions transforming the dental laboratory sector.

The user interface comprises several parameters, such as the button for the furnace, program stop and starts keys, countdown function, program running curve, correct temperature display, and program selection.

During sintering, finely grained ceramic or metal materials are heated to temperatures below the melting point of the main components. The shape of the workpiece remains unchanged. The material compresses and shrinks in size. Under the influence of temperature, a green body is formed which hardens and solidifies. Such products gain their final properties after sintering, such as hardness, strength or thermal conductivity. In addition, during restoration planning, sintering shrinkage is taken into account – the object is made bigger by a factor of shrinkage.

Incorrect temperature setting: Failing to set the necessary temperature on top of dental furnaces is one of the most common mistakes made. Setting right temperature when using sintering furnaces can be challenging since wrong temperatures may be high or low. In other words, an option must be chosen basing on correct heat that allows for proper working of a given process; this means too high heat can melt down dental material changing its shape or causing internal cracks within it.

Stay up to date with our monthly e-newsletter

Bionics Consortium Pvt. Ltd. is a premier Indian company specializing in the manufacturing, supplying, and exporting of laboratory and scientific equipment, available in both standard and custom designs.

Copyright © 2024 Bionics Consortium Pvt. Ltd – all Rights Reserved.