Stay up to date

Stay up to date with our monthly e-newsletter

* We will never share your email address & you can opt out at any time, we promise.

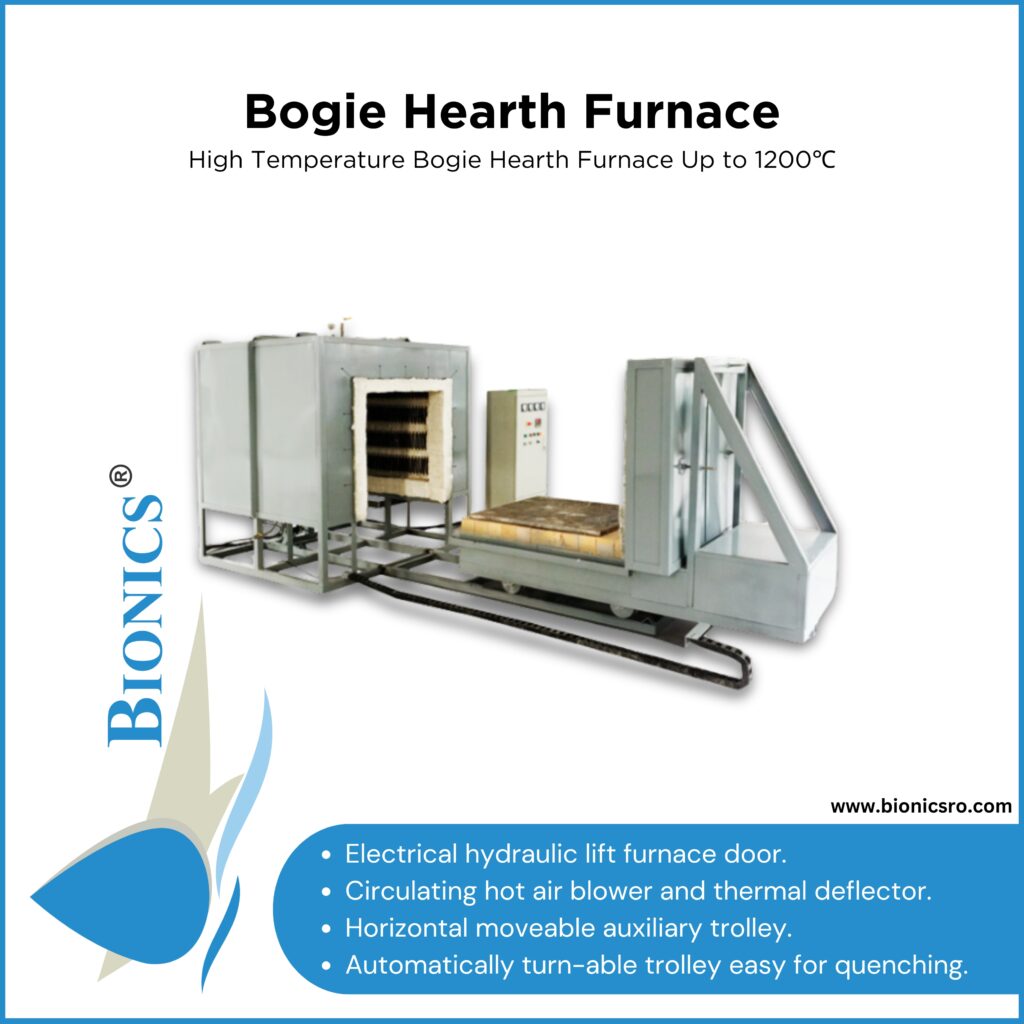

Bionics Consortium is one of the leading manufacturers of Bogie Hearth Furnace in India. These furnaces are robust and easy-to-use heat treatment equipment used for tempering, annealing, homogenising, recrystallization, etc. up to a temperature range of 1150 °C, which provides good results for such fine processes as soft annealing/normalising and stress-relieving. The furnace chamber is insulated with high-temperature fibre insulation and mineral wool, which ensures accuracy as well as easy maintenance. It has circulation fans combined with motorised dampers for cooling down purposes. Our Bogie Hearth Furnace is an automated, high-quality, energy-efficient tool for treating ferrous and nonferrous metals, meeting international standards and quality assurance.

The bogie hearth furnace is designed to heat large steel pieces to temperatures ranging from 250 to 1150°C. The bogies carrying fork trucks or overhead cranes are cooled within the furnace before being removed. There is high temperature fibre insulation and radiation heating elements on the side walls and bottom of the furnace. Bionics Consortium offers a wide range of industrial furnaces and ovens that are designed to suit various load sizes, production volumes, and materials with fast delivery and high quality guaranteed.

With continuous innovation, we have become one of the top suppliers who build custom-built furnaces or commercial heat treatment that satisfies our customers’ needs every time around the world. Being a global company, Bionics Consortium acts as a reliable partner, ensuring success irrespective of whether a big or small business entity or sector needs it.

High temperature applications include sintering, hardening, annealing, and normalising, while low temperature applications involve tempering and stress-relieving. Our bogie hearth furnaces are energy-saving and also equipped with control systems for ramping, soaking, and cooling rates.

The bottom of the furnace is motor-driven insulated and fire-resistant for safety as well as durability. It also has pneumatic sealing, which automates processes. The bogie-hearth furnace provides high efficiency, thus saving on energy consumption, coupled with high-quality products that meet the highest standards.

The bogie hearth furnace is an industrial furnace designed for large-scale heat treatment processes with even distribution of heat as well as ease in loading, especially on bulky work-pieces.

1. Designing and building together with the client

Customer-specific application processes are the basis for designing bogie hearth furnaces in close cooperation with them. Electric or natural gas can be used for heating, and it can also be multizoned, temperature controlled, forced cooled, and operated either under atmospheric or pressurised conditions. Construction is done according to customer specifications; automatic drive systems may be incorporated where necessary.

2. Optimum thermal insulation

Heat insulation on Bogie Hearth Furnace units gets optimised using the user process as a reference point. Lightweight refractory bricks are employed in cases where processes take longer while ceramic fibre modules suit fast ones. For heavy batches, fireclay or refractory concrete will suffice, sometimes combined with other thermal insulating materials.

3. A range of industrial furnaces

For ease of use when loading input materials, bogie hearth furnaces have options such as swing batch loaders or rail-bound ones fitted with lifting doors, which can also be forced cooled as per the operator’s needs.

A bogie hearth furnace comes in handy for lower temperature ranges, just like a chamber type with air circulation fans would do so too. Heat-resistant air guides together with high static pressure radial circulating fans are used; the air is sucked out from the furnace chamber, thus creating an upward flow over the floor for better temperature uniformity within room space.

This standard practice of heat treating large components is done in bogie hearth furnaces through gas heating. Small areas tend to employ electric heating systems. The bogie hearth furnace is typically rigid.

1. Heating Steel and Aluminium Plates with a Bogie Hearth Fan Furnace

The Bogie hearth fan furnace is made for heating steel and aluminium plates within the range of 180-630°C. It moves on a rack and pinion system and is heated electrically by coils set into the ceiling. There are three control zones on the furnace, including hot-gas circulators and adjustable cooling air fans.

2. Bogie Hearth Furnace for Soft and Normalising Annealing

The purpose is stress-free soft annealing as well as normalising sheet metal plates up to 16 t with batch dimensions of 1,500 x 5,000 x 1.000 mm. Two chambers can be separated from each other while high-speed burners provide it with heat.

3. Heat Treatment of Welded Constructions, Rings, and Rollers Using Bogie Hearth Furnaces

For thermal treatment of welded constructions, rings, and rollers with temperatures up to 650°C, a bogie hearth furnace is used, having a carrying capacity of up to 50 tonnes and using eight high-speed burners for heating purposes only. For temperature control purposes, additional cooling air jets (80 K/h) mounted at a rate of 3,500 m/h are provided.

Stay up to date with our monthly e-newsletter

Bionics Consortium Pvt. Ltd. is a premier Indian company specializing in the manufacturing, supplying, and exporting of laboratory and scientific equipment, available in both standard and custom designs.

Copyright © 2024 Bionics Consortium Pvt. Ltd – all Rights Reserved.