Stay up to date

Stay up to date with our monthly e-newsletter

* We will never share your email address & you can opt out at any time, we promise.

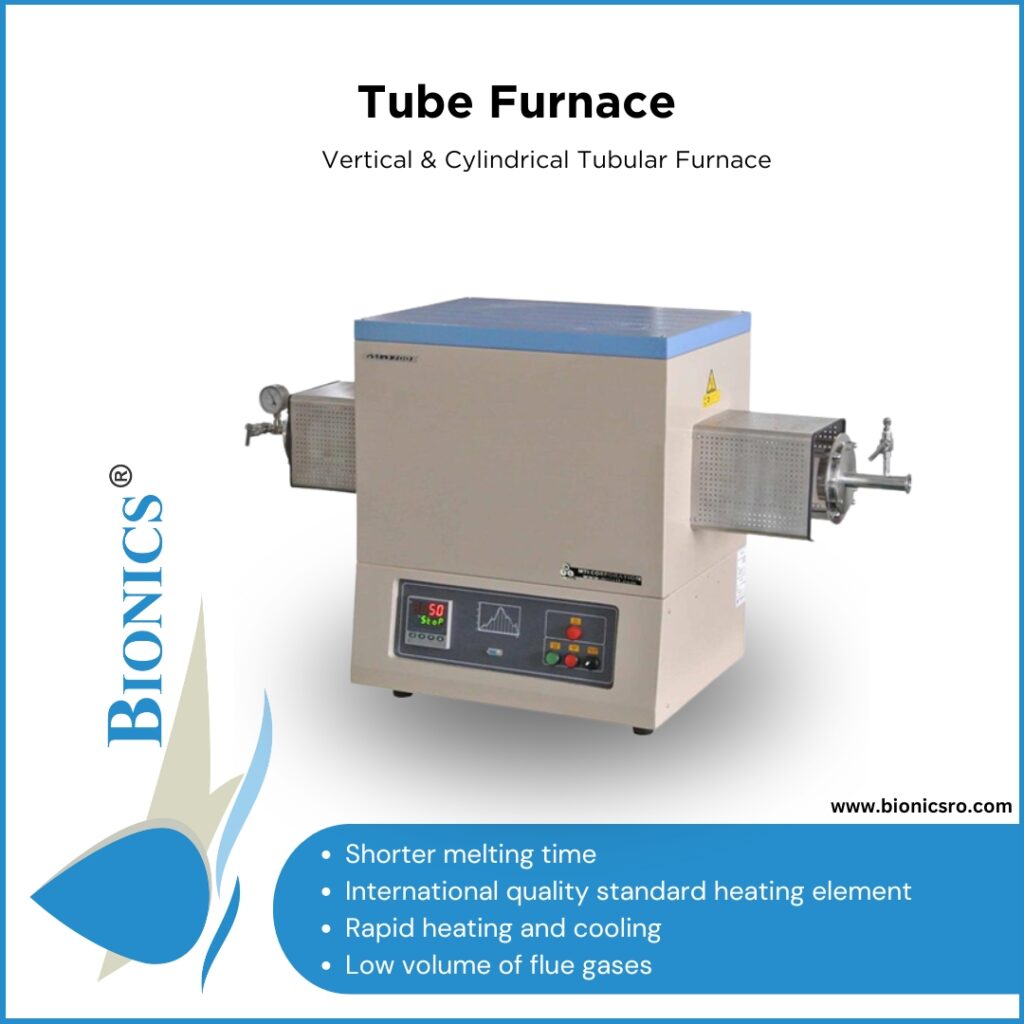

Bionic Consortium is one of the leading manufacturers of high-quality tube furnaces in India and manufactures single-zone, multi-zone, vertical, and rotary tube furnaces. Furthermore, split tube furnaces are also produced by them within the range 800°C to 1800°C.

These furnaces have good temperature stability and can be ordered with different options, such as a digital controller, programmer, logger, over-temperature protection, insulation plug, and radiation shield. Some tube furnaces come with built-in work tubes, whereas others require to be separately fitted. It is surrounded by the heating elements, which give it a good temperature distribution. It’s a device you can find in most labs with many uses, like material heat treatment and crystal growth.

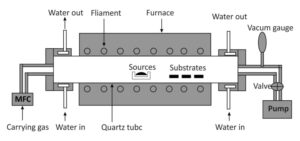

These are heating appliances used in various processes that include crystallization, polymer analysis and treatment of materials at specific temperatures. It contains coils of heaters surrounded by thermally insulating material in a tubular chamber. Besides, they may have a working tube or vessel. Uses can range from chemical vapour deposition, heat treatment to synthesis for materials purposed in the laboratory. Tube furnaces fall into three categories: Drilling to extract oil and gas involves rotary, horizontal, gradient, and diffusion methods. They are employed to move heat from one fixed point in the tube to another fixed point through specified volume of material. Such modern materials achieve operational temperature limits up to 1800°C as molybdenum disilicide does.

Bionic Consortium is one of the leading manufacturers of high-quality tube furnaces in India and manufactures single-zone, multi-zone, vertical, and rotary tube furnaces. Furthermore, split tube furnaces are also produced by them within the range 800°C to 1800°C. These furnaces have good temperature stability and can be ordered with different options, such as a digital controller, programmer, logger, over-temperature protection, insulation plug, and radiation shield. Some tube furnaces come with built-in work tubes, whereas others require to be separately fitted.

It is very significant to note that for a small number of samples, the tube furnaces are most useful. Moreover, they are smaller in size and therefore faster in heating up than chamber furnaces in these applications. This is mainly due to the fact that sealed working tubes are the primary use of these types of furnaces because once the working tube is sealed, there is no possibility for its content to interfere with other substances. Similarly, these tubes act as shields for contaminants from outside getting into the furnace and also act as a means by which the ambient environment around samples can be regulated; this is highly desirable for most applications.

These furnaces include split/non-split, rotary, gradient, and oscillating ones. Split-tube furnishers have middle hinged bodies, thus making them popular among school laboratories and research institutions. It doesn’t open horizontally or lengthwise but rather has a process tube penetrating through a stationary heating cylinder, making it ideal when batch production extends up to standard repetitive sample sizes.

Horizontal Tube Furnace

Vertical Tube Furnace

Split

Rotary

These versatile devices are used in a variety of heat treatment processes such as purification, annealing, aging, drying and coating. They have constant and uniform thermal heat distribution, which makes them useful for applications like thermocouple calibration. Some industries that use them include schools and colleges, research and development laboratories, chemical industries, medical, ceramics, biomedical, pharmaceuticals, etc. Several other uses consist of purification, surface treatment, condensation, strengthening, heat treatment, soldering, and calcination and deoxidation, Consolidation, stress relief, thermocouple calibration, fuel cell testing, catalyst development.

The industrial tube furnaces are used in different heat treatment processes, such as annealing a way to harden or temper metals or alloys with accurate temperature control and the desired mechanical properties.

Models involved in ceramics manufacturing include those that provide the necessary sintering process by heating a furnace chamber along with the ceramic material in order to densify it, while annealing ceramics makes their mechanical properties trend upward when they warm up to specific temperatures then cool down. For instance, they can be utilised in several areas, such as heat treatment, material synthesis, ceramic processing, brazing/soldering, annealing, etc., depending on the users’ requirements.

Tube furnaces play roles during brazing and soldering since they operate joining metallic elements using a filler, hence suitable for vacuum or controlled atmosphere brazing.

Annealing is another area where tube furnaces are being employed, whereby materials are heated or cooled so that their mechanical properties become improved. The preferred choice between them depends on the customer needs because some go for one furnace doing all these operations.

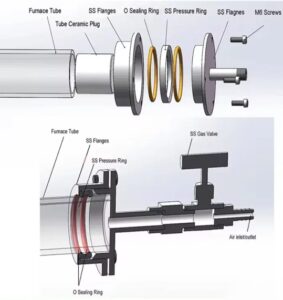

In order to ensure that the tube furnace has a uniform length within ±5°C temperature uniformity tolerance, insulation plugs are fitted and heated zones are levelled.

Bionics Consortium manufactures single-zone as well as multi-zone tube furnaces that have one or many controllers for use in the synthesis and purification of organic and inorganic compounds. Additionally, they offer multi-zone models with two to ten zones, both horizontal and vertical configurations; however there are also customized tube furnaces within this country available at reasonable prices.

Tube furnaces are strong industrial means that can stand up to the most demanding heating requirements. The main component is a cylindrical ceramic tube. After that, they have been placed around it so that it maintains an even temperature along its entire length. Our rotary tube furnaces are made from MS powder-coated alumina ceramic fibre, with chamber designs having single-zone or multi-zone zoning systems.

Bionics Consortium supplies Rotary Tube Furnace with programmable controller certified by NABL with an alternative of PLC having HMI that is provided with LED double display, which displays set value, current value, and remaining time. The temperature control panel comprises a heating start indicator and load indicator accompanied by an audio-visual alarm (sound light). The imported heating elements from Japan are chosen according to temperature requirements, i.e., lanthanum chromite MOSI2 for 1800°C and 1700°C, respectively, while Silicon C.

A laboratory tube furnace is an apparatus that provides precise temperature control and uniformity. Tube furnaces are used to house samples and heat them up. The work tube is surrounded by the heating elements, which give it a good temperature distribution. It’s a device you can find in most labs with many uses, like material heat treatment and crystal growth.

Compared to chamber furnaces, tube furnaces are characterised by smaller volume capacity and faster heat-up rates, making them suitable for small sample processing. Sealed work tubes also prevent the furnace structure from contamination, thus providing a modified atmosphere around the samples as well.

These different types of tube furnaces include split, non-split, gradient, rotary, oscillating systems, etc. For example, the orientation of the work tube may either be horizontal or vertical depending on whether it is split or non-split.

The uniform length section provides the most consistent temperature within the tube furnace. This zone comes into play when a very accurate heating system is required in some experiments. You can increase this area by adding special insulating plugs and employing more heating sections within your furnace. A specific region within the pipe may have its temperature maintained at 5°C from an arbitrary point so long as it remains approximately 5 degrees Celcius, but that may vary depending on which type of oven one has chosen for his or her experiments or studies.

Stay up to date with our monthly e-newsletter

Bionics Consortium Pvt. Ltd. is a premier Indian company specializing in the manufacturing, supplying, and exporting of laboratory and scientific equipment, available in both standard and custom designs.

Copyright © 2024 Bionics Consortium Pvt. Ltd – all Rights Reserved.